Casting for Orthotics

If you’ve ever had custom foot orthotics, there was a casting done of your feet. This cast is used to create the actual orthotic that you wear. There are many different ways to cast the foot and they all have different benefits to the practitioner.

2D vs 3D casting for orthotics

When creating a custom foot orthotic, a 3D cast of the foot must be taken. This ensures that the actual shape of the foot is captured instead of estimating the shape.

2D images can be used as a tool to see where pressure points are on the foot. These pressure points are important to determine when creating a custom foot orthotic, but technology is not always necessary. During an assessment, the foot is examined many different ways to tell the practitioner where these pressure points are. Information such as shoe wear and calluses on the feet can provide valuable information on where pressure is. When these pressure points don’t line up with how the foot is moving when walking, further investigation can be important. A specific shoe or activity can cause pressure points that can affect how the custom foot orthotic will function.

Plaster casting for orthotics

Plaster casting is the oldest form of casting a foot. It is a very reliable form of casting as it creates a great shape of the foot. This technique may not be as popular because it takes longer to cast, and is messier.

It can also be more time consuming at the beginning of the manufacturing process because extra material is added to the cast before creating the shell of the orthotic. This extra material is typically added because the cast is taken without any weight on the foot. This non-weight bearing cast doesn’t account for any splay of the soft tissue. When we go from sitting to standing, the soft tissue in the feet spread out. This extra material is added to the cast to account for the soft tissue splay.

Personally, I have found that there are some feet that do much better with this type of cast, but the majority can work with any 3D technique.

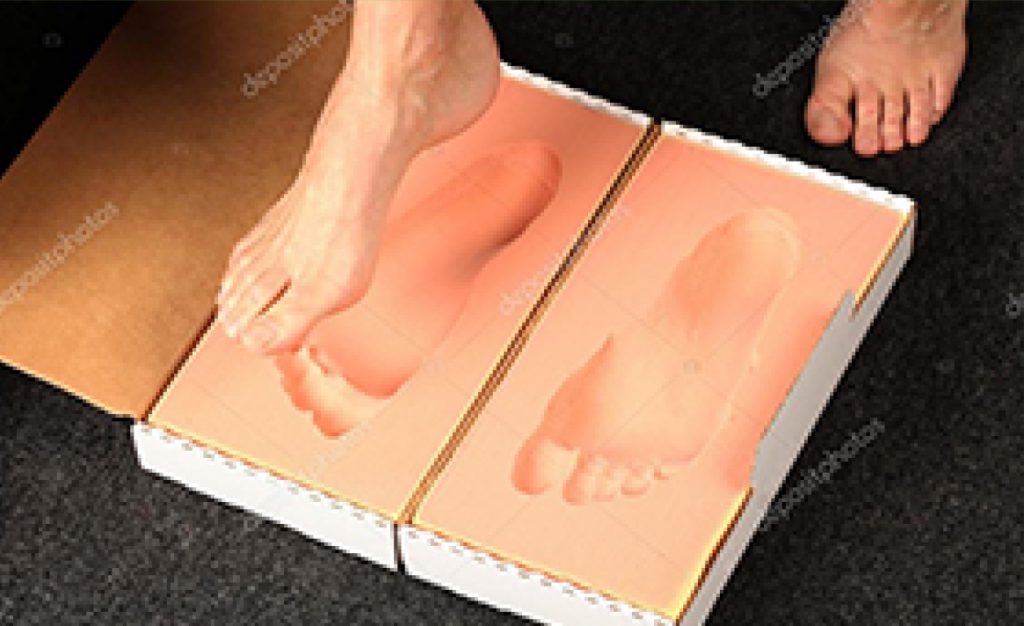

Foam box casting

Foam box casting

Foam box casting is a popular form of casting. It is much faster to cast the foot, but it takes more practice to perfect the casting technique. It accounts for the soft tissue splay of the foot. This is because the cast is taken in either a semi-weight or full-weight bearing position.

A semi-weight bearing cast is popular because it is preferred for a common foot type, a low/collapsed arch. It captures the arch of the foot before it collapses and it provides some pronation which is important for shock absorption.

A full-weight bearing cast is typically taken for a rigid high arched foot. Casting full weight bearing helps to prevent overcorrection as this could lead to pain in places like the hip and lower back.

Digital casting

Digital casting is a newer form of casting that is becoming popular. There are many different methods such as a laser scan of the bottom of the foot, or a camera made to create a 3D image of the foot. This is a great way of casting to reduce waste in the manufacturing process.

Other 3D casting techniques

There are other 3D casting techniques that provide similar results to the above methods. The important part is getting a 3D image of the foot. Most of the time, the best casting technique is what the practitioner is most comfortable with and what they prefer using.

You must be logged in to post a comment.